The Sydney, Australia-headquartered tna group’s March 6 purchase of Woerden, Holland-based Florigo International BV provides it with access to a wide range of continuous snack and french fry processing equipment manufacturing, and engineering and installation expertise. Florigo will retain its brand name and become integrated into tna.

The deal includes patented continuous vacuum frying systems, french fry lines, multi zone fryers and technology to reduce acrylamide formation. Together with the addition of FOODesign to the group last year, the acquisition of Florigo enables tna to further boost its processing solutions capabilities and meet the growing needs of an expanding global customer base.

With over 60 years of industry experience, Florigo specializes in the design and manufacture of innovative frying technology for large and medium-size snack and potato processing lines, including washing, de-stoning, peeling, slicing, blanching, drying, frying, cooling and freezing equipment. The incorporation of Florigo’s products into tna’s extensive portfolio of packaging, processing, distribution, seasoning, coating, weighing, metal detection and identification equipment will broaden its position as a leading provider of start-to-finish single source solutions for the snack industry.

Florigo’s renowned engineering knowhow, which includes patented vacuum frying and de-fatting technology, is now at the full disposal of tna’s global team. The company’s unique vacuum technology enables manufacturers to cook at lower temperatures, preserving the natural colors, textures and flavors of product while reducing the formation of acrylamide by up to 95%.

Vacuum frying is also ideal for products that are high in natural sugar, such as sweet potatoes and fruits, thus opening up opportunities for creative product ideas to help tna’s clients cater to the increasing demand for healthier snacks in today’s market.

Florigo also has solutions to reduce acrylamides in more conventional frying, along with more efficient process and reduced fat content.

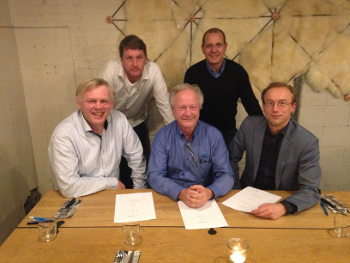

Commenting on the acquisition, Michael Green, managing director at tna, said: “We’re very excited to integrate Florigo Industry into our family…The snacks market has experienced significant growth over the past few years and more of our customers are looking for quality equipment that can handle greater product volumes. Together with FOODesign, the incorporation of Florigo gives us even more flexibility for offering customers a range of solutions – from smaller direct-fired batch fryers to complete french fry production lines with capacities of up to 30,000 kilograms per hour, enabling us to deliver customized, efficient turnkey solutions to the wider snacks industry.”

Commenting on the acquisition, Michael Green, managing director at tna, said: “We’re very excited to integrate Florigo Industry into our family…The snacks market has experienced significant growth over the past few years and more of our customers are looking for quality equipment that can handle greater product volumes. Together with FOODesign, the incorporation of Florigo gives us even more flexibility for offering customers a range of solutions – from smaller direct-fired batch fryers to complete french fry production lines with capacities of up to 30,000 kilograms per hour, enabling us to deliver customized, efficient turnkey solutions to the wider snacks industry.”

“The acquisition allows us to bring our technology closer to customers in Europe, Asia and the Middle East, reducing lead times and accelerating time to market. At the same time, it provides our customers with access to unique innovative technology and research capabilities, enabling them to test and develop products in a controlled cost-effective environment,” said Bob Fritz, director of business development. “We see the Woerden facility as our European centre of excellence for processing. With manufacturing for processing in Portland, Oregon, USA, as well as in Woerden, we are a good position to support the growing customer base.”

“Joining the tna group was an obvious choice for us,” stated Luc-Jan Wolpert, director at Florigo. “It has built up a strong reputation in the industry throughout the years and shares our commitment to the highest level of performance and service excellence. Its expansive network of sales, technical support and manufacturing sites will allow us to reach food manufacturers around the world. At the same time, our existing customer base will benefit greatly from tna’s range of start-to-finish solutions, opening up a breadth of new opportunities for both companies and their customers.”