Farm Frites, a Dutch family business specializing in producing frozen and chilled french fries and other value-added potato products, was presented a charity voucher worth €2,000 after winning the Golden Fry competition organized by TOMRA Sorting Food during the Interpom/Primeurs exhibition in Kortrijk, Belgium.

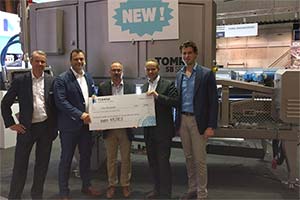

Taking part in the charity voucher presentation are (left to right): Jan van de Wolfshaar, Steve Raskin, Ron Packbier, Leon Boer and Adriaan de Bruijne.The competition centered around the processing of 20 kilograms of fries, one of which was made of gold. Ron Packbier, an engineer at Oudenhoorn, Holland-headquartered Farm Frites, came closest to correctly guessing the moment when the golden fry would be ejected from the line by the TOMRA 5B sensor-based sorter, and was thus awarded the voucher. He chose UNICEF, a charity that has distributed lifesaving aid to needy children around the world for almost 70 years, as the recipient.

Taking part in the charity voucher presentation are (left to right): Jan van de Wolfshaar, Steve Raskin, Ron Packbier, Leon Boer and Adriaan de Bruijne.The competition centered around the processing of 20 kilograms of fries, one of which was made of gold. Ron Packbier, an engineer at Oudenhoorn, Holland-headquartered Farm Frites, came closest to correctly guessing the moment when the golden fry would be ejected from the line by the TOMRA 5B sensor-based sorter, and was thus awarded the voucher. He chose UNICEF, a charity that has distributed lifesaving aid to needy children around the world for almost 70 years, as the recipient.

“In everything we do, we strive to contribute to a more sustainable environment, which also includes our children, who are our future,” said Packbier. “All children deserve a healthy life and we’re happy to be able to contribute to the good work that UNICEF does.”

Steve Raskin, TOMRA Sorting Food’s sales director for the EMEA region, added: “We are very pleased that Farm Frites chose UNICEF as its charity because it’s a very worthy cause. We hope that the donation can contribute to a better world for children everywhere and give them the future they deserve.”

Steve Raskin, TOMRA Sorting Food’s sales director for the EMEA region, added: “We are very pleased that Farm Frites chose UNICEF as its charity because it’s a very worthy cause. We hope that the donation can contribute to a better world for children everywhere and give them the future they deserve.”

The TOMRA 5B, the latest state-of-the-art high volume sorter for the vegetable, potato and fresh-cut processing industries, offers a highly efficient, intuitive sorting solution that has been designed to improve yields and product quality, with minimal product waste and maximum uptime. These benefits are made possible via three integral features: the delivery of optimum performance, improved ease of use and enhanced hygienic design.

The sorter achieves optimum performance by combining TOMRA’s smart surround view technology with 360-degree inspection. The technology features high-resolution cameras, as well as high intensity LEDs for improved light intensity for optimal product appearance. This combination reduces false rejection rates and improves product quality by identifying each object, in turn improving color, shape detection and foreign material, and ensuring product quality.