The international frozen food market is in a continuous growth mode due to several factors, according to the OctoFrost Group: the increase of the world population, shortages of food in some regions, demographic shifts, and the rising demand for frozen components in the food industry.

Another important factor is the behavioral changes of consumers in developed countries, points out a press release issued by the Malmö, Sweden-based company on January 5. The increasing number of women who work away from home and thus have less time for cooking, plus the rising number of people who live alone, are stimulating ongoing growth in the frozen food industry.

In order to keep up with demand, frozen food producers are relying on more efficient IQF freezing equipment. OctoFrost has been supplying such technology since 1999, when founder Ruben Larsson launched the company as IQF Frost AB.

Over the years consumers have become more informed about the superiority and convenience of frozen products, and increasingly regard frozen fare as a more suited alternative for maintenance of a healthy lifestyle. In economic and marketing terms, this acceptance is reflected in larger dedicated space for frozen offerings in supermarkets.

The international frozen food market is expected to be worth almost $308 billion by the end of 2020. From a geographical point of view, Europe is experiencing the most significant growth. This is especially evident in rising demand for IQF products.

Among major players in the global frozen food sector that rely on IQF technology are Nestlé, General Mills Inc., Heinz, Unilever Plc, McCain Foods, The Schwan Food Company, Iceland Foods Ltd., Birds Eye and Tyson Foods.

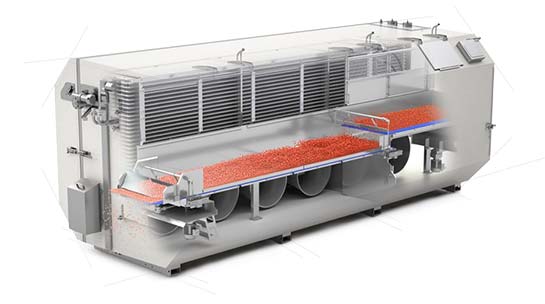

Today’s leading producers must consistently provide top quality frozen products that balance appearance and nutritional value. This can only be obtained by using high-tech freezers of innovative design, such as OctoFrost™ IQF tunnel freezers. The IQF process of individually quick freezing each unit of product separately by blasting cold air at high velocity through a fluidized bed results in better flavor and texture, as well as preservation of higher nutrition levels than product frozen with different methods, according to OctoFrost.

The company high-performance freezers, built for food safety, maximum yield and high sustainability, feature patented technology of bedplates and fluidization which increases quality and yield of fresh-frozen products. Its OctoFrost IQF model, which is especially adept for freezing fruits, vegetables, cheese, seafood, meat and poultry, features a mono-block design and affords easy interior access for reliable and swift cleaning. The kit has been equipped with air knives that blow high pressure air in the coil during production, which will help keep the coil free from product particles, prevent it from building up snow and optimize run time between defrost. More spray nozzles for warm water have been installed to decrease down time and speed up the cleaning process.

OctoFrost’s octagonal design and aerodynamics is optimized for high capacity per hour, yet is sustainable with usually more than 10% less energy consumption than similar products on the market. A dry air infusion system has been installed in the operating panel, lights and motors, eliminating the challenge that many food producers face of condensation, due to the variation of temperature in the freezer. Additionally, the freezer has been reinforced with stronger fins in the coil and an anti-slip shockproof floor.

For more information, visit www.octofrost.com.