The Case Packing Systems (CPS) team will hold forth at Stand E048 in Hall 7.1 during the March 24-27 Anuga FoodTec in Cologne, Germany.

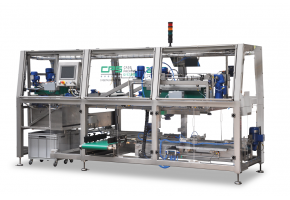

Since its foundation in 1988, the Stramproy, Holland-headquartered company has focused on designing and building fully automatic end-of-line case packing systems with special emphasis on flexibly-packed products and trays. CPS equipment is proficient at efficiently handling numerous types of items – from frozen vegetables, fruits and potatoes to fish, meat, poultry, baked goods and more – at high rates of speed.

There are other benefits as well. CPS machines pack products more compactly than is possible by hand, and therefore achieve substantial savings in labor costs. Packing in shelf-ready boxes has also become an important feature, and CPS uses its deep expertise and experience to produce high-quality case packers.

There are other benefits as well. CPS machines pack products more compactly than is possible by hand, and therefore achieve substantial savings in labor costs. Packing in shelf-ready boxes has also become an important feature, and CPS uses its deep expertise and experience to produce high-quality case packers.

Flexible bags, MAP trays or flowpacks in all shapes and sizes are packed fully and automatically, horizontal and vertical, at high speed in RSC boxes, cardboard trays, crates, pallet boxes and wheeled containers.

In order to supply customer-specific case packing lines, CPS integrates X-ray scanners, metal detectors, check weighers, coding systems and case erectors in its systems. The total case packing line is normally supplied with complete product and box supply systems, and may also include merging and buffering systems, to the final discharge of sealed boxes, which is completely designed and constructed by CPS engineers in house.

The company produces a full range of industrial case packers. If required, collaborations can be set up with partners to deliver complete turnkey projects, including packaging machines and palletizing systems.

For more information, contact Henri Veltmans by phone (+31(0)495 566 600) or e-mail (h.veltmans@c-p-s.nl).