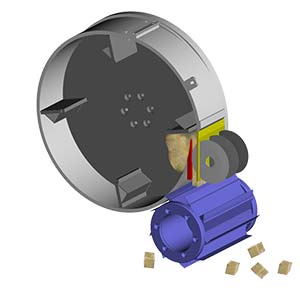

Food cutting specialist FAM will exhibit its FAM Tridis™ 240 high capacity dicer at the November 27-29 Interpom-Primeurs show in Kortrijk, Belgium. Designed for highly demanding frozen vegetable, fruit and french fry processing, the machine is said to increase maximum capacity previously known in the industry by 10% or more, while maintaining excellent cut quality.

The Kontich, Belgium-based equipment manufacturer developed the high-capacity tri-dimensional dicer in close consultation with leading companies in the food processing sector. Together with these partners it identified key performance indicators in order to provide greater capacity, higher cut quality, hygiene, simplicity and maintenance advantages.

The Kontich, Belgium-based equipment manufacturer developed the high-capacity tri-dimensional dicer in close consultation with leading companies in the food processing sector. Together with these partners it identified key performance indicators in order to provide greater capacity, higher cut quality, hygiene, simplicity and maintenance advantages.

Improvement in cut quality required geometric optimization of the slicing knife to produce a cleaner first cut. Then the product is guided meticulously through circular and crosscut knife spindles, leading to a precise cut and higher yield with less slivers and fines.

Capacity of the FAM Tridis 240 was boosted by running at a higher velocity and by reducing the cutting zone length. By moving the cutting tools closer together and decreasing product transit time, the capacity was raised without compromising on cut quality.

Problem-free performance is made easy for operators by keeping the design of the machine simple, and by offering auxiliary tools that make changing slicing components a quick and simple process. The Set & Forget™ technology for the circular knife spindle and the slicing guide makes fine-tuning the cutting tools an easy job.

Problem-free performance is made easy for operators by keeping the design of the machine simple, and by offering auxiliary tools that make changing slicing components a quick and simple process. The Set & Forget™ technology for the circular knife spindle and the slicing guide makes fine-tuning the cutting tools an easy job.

The FAM Tridis 240 has clear benefits regarding maintenance. Features include a movable electrical cabinet that provides easy access to the drive compartment and the cartridge system for removing the shafts and its bearings, which are lifetime greased and sealed.

Finally, there is easy accessibility for cleaning and maximum product guidance. The machine has an open frame with only slant surfaces and no visible wires or hidden corners.