MeaTech 3D, a Rehovot, Israel-headquartered cultured meat technology company, recently held a tasting event with anchor investors, including members of the Rami Levy Group, the Pozilov family and Eli Nidam. Among other attendees were Stella Weinstein, secretary general of Yamina (the political party leading Israel’s governing coalition) and representatives from the Manufacturers’ Association of Food Industries.

The event took place at MeaTech’s new offices in the Rehovot Science Park, the hub of the nation’s food tech sector. Guests toured the labs and R&D facilities, visited the company’s 3D printing capabilities, and tasted hybrid chicken nuggets made with plant protein and cultured chicken fat biomass developed by MeaTech’s wholly owned Belgium-based subsidiary.

“We believe that plant-based hybrid products combined with cultured fat represents the next generation in meat substitutes,” said CEO Arik Kaufman. “The use of cultured fat offers a meatier taste and mouthfeel that is closer to conventional meat products. As part of MeaTech’s market entry strategy, we are moving ahead with the establishment of a new pilot plant and R&D facility in Belgium that will advance our R&D and technology capabilities in the production of cultured chicken fat biomass and help accelerate the entry of our products into global markets.”

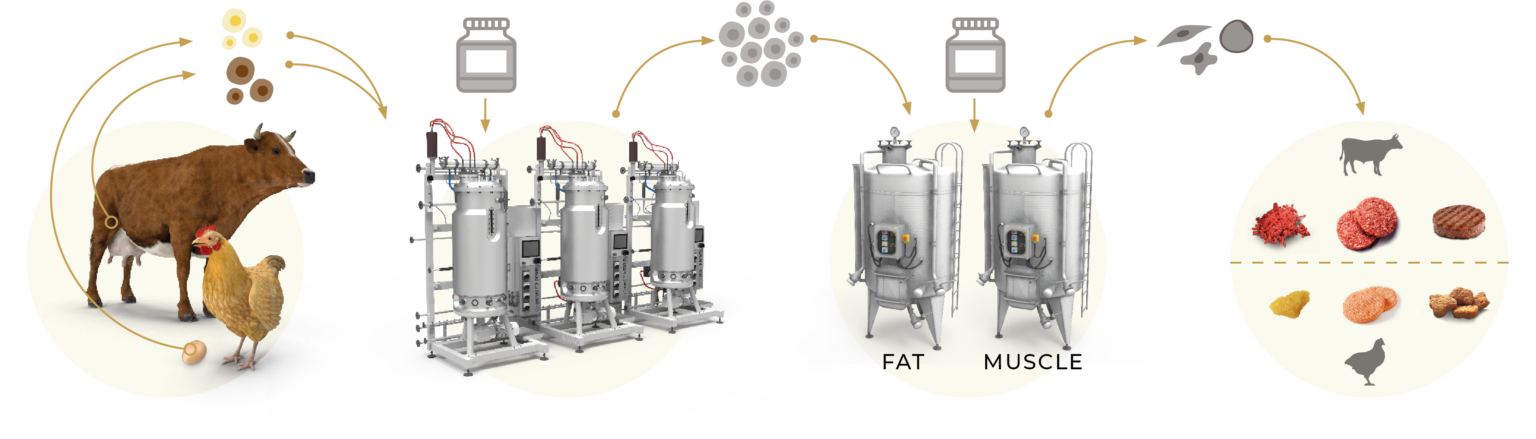

How does the cultured meat production process work? First animal cell lines are developed to reliably express particular characteristics. Stem cells are transferred to bioreactors for exponential growth under ideal conditions. Upon reaching sufficient cell quantities, stem cells are differentiated into fat and muscle cells. Then unstructured cell-based products (beef or chicken): fat, ground, hybrid or formed.

Established in 2019, MeaTech 3D is listed on the Nasdaq Capital Market under the MITC stock symbol. Now in the process of expanding activities to California, USA, the founders believes cultivated meat technologies hold significant potential to improve production, simplify the supply chain and offer consumers a range of new product offerings.

The company’s business plan embraces alternative industrialized animal farming methods that dramatically reduce carbon footprint, minimize water and land usage, and prevent the slaughtering of animals. By adopting a modular factory design, MeaTech 3D will be able to offer a sustainable solution for producing a variety of fresh and frozen beef, chicken and pork products, both as raw materials and whole cuts. The company will also provide meat manufacturers and retail businesses with production equipment.