Lübeck, Germany-headquartered Baader has completed its majority share acquisition of Akranes, Iceland-based Skaginn 3X. The transaction brings the long-standing food processing engineering practices of Baader together with the innovative freezing, cooling and processing expertise of Skaginn 3X.

Both companies will continue to manufacture equipment at current site locations, and no workforce reductions are intended with this joint venture as existing capacities will be needed to support future growth.

An integration phase will focus on the creation of a new global organization consisting of a coordinated joint sales force. For the time being, established sales representation and contacts will remain in place to ensure ongoing familiarity in the early phases of the integration process.

“Our overall mission is to be the one go-to partner for customers within the fish industry, as we have done for over 100 years. Our aim is to provide and service innovative stand-alone equipment and system solutions within all major segments of fish that are best in class, based on strong engineering and deep-rooted knowledge of the industry,” said Petra Baader, executive chairwoman of Baader.

“I am pleased that were are joining forces with Baader. Our focus for the past 40 years has always been on developing innovative products for the industry. With Baader’s global distribution network, Skaginn 3X can continue to focus on innovation and fully utilize the manufacturing capabilities in Iceland to serve the new Baader sales and service network,” stated Ingólfur Árnason, chief executive officer of Skaginn 3X.

Looking to the future, customers stand to benefit from even more jointly tapped potential the two companies synergistic relationship.

“Together, we will not only strengthen our competencies regarding all fish species, but we will also be able to tune the resource processability,” said Robert Focke, managing director of Baader. “Through the Skgaginn 3X sub-chilling technology, it will be possible to process fish even more precisely while conserving resources and maintaining quality.”

Freezing Technology in Demand

Demand for frozen seafood has surged during past year, as lockdowns imposed by governments in response to the coronavirus pandemic has prompted consumers to stockpile extended shelf life fishery products. As such Skaginn 3X has seen a significant interest in industrial freezing equipment solutions from customers gearing up production of frozen products.

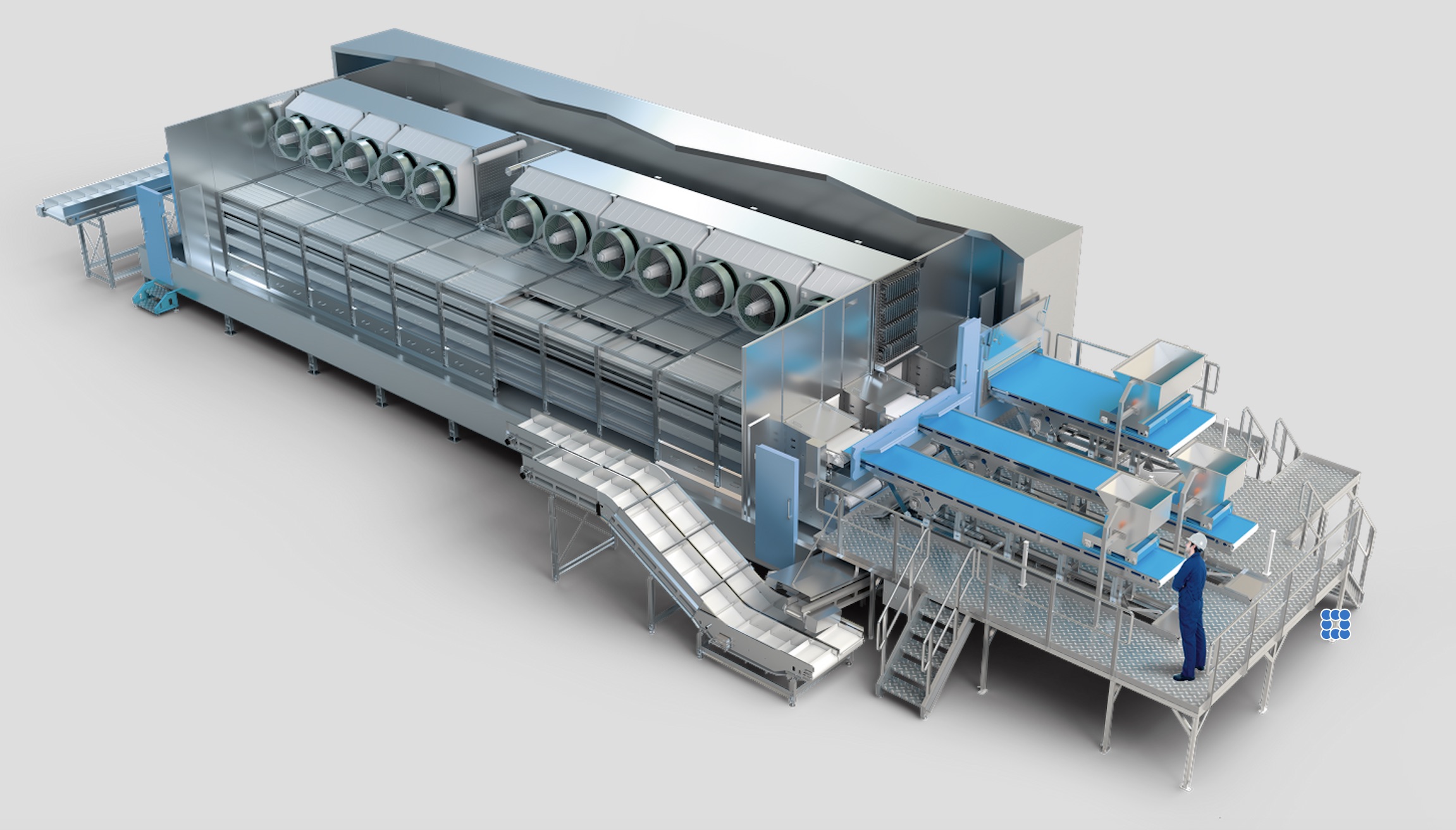

One of the systems in steady demand is the Automatic Contact Freezer (pictured above), which features short loading and freezing times and uses non-pressure, horizontal freezing to maintain optimal quality. It is fully automated and available in a range of capacities, up to 100 tons per 24 hours for a single unit, which is attractive to producers who are looking to get quality product to markets as quickly as possible.

Another system that has become more popular as production increasingly shifts to freezing is the ConTech IQF Freezer (picture below), which combines crust and full-freezing in a single unit. Featuring the patented TCAB belt, the flexible and cost-efficient equipment is designed to freeze fish and other foodstuffs approximately 40% faster than conventional IQF units.