With consumers increasingly demanding convenient, fast-to-prepare foods, frozen fruits and vegetables such as green peas, beans and berries are a growing segment of the retail grocery market. At the same time, food safety regulations are tightening and shoppers have come to expect impeccable products. A major concern is the potential presence of foreign materials (FM) such as small stones or pebbles, shards of glass, wood or plastic in packaged goods.

Optical sorters with InGaAs cameras are highly effective in detecting and removing these objects. Bühler, which pioneered the use of this sensor technology in optical sorting in 2007, is now introducing InGaAsHD. With double the resolution, the latest high-definition cameras are able to identify undesirable foreign matter down to half the size previously possible, resulting in substantially better detection and removal. InGaAsHD, now available in the SORTEX E product range, enables processors of frozen fruits, vegetables and other items to meet the highest safety requirements, while ensuring maximum quality of their product.

Optical sorters with InGaAs cameras are highly effective in detecting and removing these objects. Bühler, which pioneered the use of this sensor technology in optical sorting in 2007, is now introducing InGaAsHD. With double the resolution, the latest high-definition cameras are able to identify undesirable foreign matter down to half the size previously possible, resulting in substantially better detection and removal. InGaAsHD, now available in the SORTEX E product range, enables processors of frozen fruits, vegetables and other items to meet the highest safety requirements, while ensuring maximum quality of their product.

More consumers have come to appreciate that frozen fruits and vegetables can be nutritionally superior to so-called fresh produce sold at retail stores. That’s because quick-freezing takes place soon after crops are picked – and harvesting is timed when they are at peak ripeness, loaded with vitamins and antioxidants.

“While increasing amounts of frozen fruits and vegetables are being processed, food safety regulations are tightening in most countries and processors have to guarantee the safety and quality of their products,” said Stephen Jacobs, global product manager at Bühler.

Among the biggest safety concerns are foreign materials, such as small stones, pieces of wood and glass, or slivers of plastic. If contained within packaged frozen food products, they will pose health risks – including lacerations, choking or broken teeth. For food processors, this could result in expensive product recalls and damage to reputation.

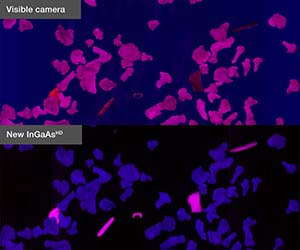

With its wide range of optical sorting solutions, Bühler has worked for decades to enable food processors to efficiently identify and remove foreign materials. This is achieved by using a variety of sophisticated detection technologies. InGaAs cameras, for instance, are very effective for separating foreign materials from good product of the same color. They are based on semiconductor sensors made from indium gallium arsenide alloy, and operate in the short wave infrared range (SWIR). As a consequence, they are able to detect even the subtlest of color differences that cannot be seen in the visible spectrum.

Bühler pioneered the use of this technology for use in packing lines, as a final check, to ensure that hard-to-detect foreign materials and packaging debris such as light colored wood in potatoes, cardboard in carrots and colored plastic in vegetable mixes are quickly identified and efficiently removed from the product stream.

Bühler pioneered the use of this technology for use in packing lines, as a final check, to ensure that hard-to-detect foreign materials and packaging debris such as light colored wood in potatoes, cardboard in carrots and colored plastic in vegetable mixes are quickly identified and efficiently removed from the product stream.

Bühler has continued to advance this technology, and the development of the new high-definition InGaAsHD cameras marks the latest step in this process.

“By combining a new hardware, software and lens package we were able to engineer a new camera with double the resolution. As a result of this in-house development, our sorter will be able to identify foreign material objects down to half the previous size,” said Benedict Deefholts, the company’s head of sensor development, in describing the key advantage of the new HD cameras.

Thanks to this advance, sorting solutions for packers of frozen fruits and vegetables now offer even better detection and removal capabilities for a wide range of foreign materials in several different stages of the processing and packing line. This is particularly beneficial for processors with stringent safety specifications such as those supplying the baby food market.

The InGaAsHD cameras are now available for Bühler’s SORTEX E product line. Processors that are already operating SORTEX E optical sorters with enhanced InGaAs cameras will be offered an upgrade option, enabling them to benefit from the improved detection performance of the new HD cameras.

Based in London, England, Bühler Sortex Ltd. is a unit of the Bühler Group, a family-owned food processing equipment and advanced materials technology company with annual turnover of approximately CHF 2.3 billion. Headquartered in Uzwil, Switzerland, it employs 10,600 people at 140 sites around the world.