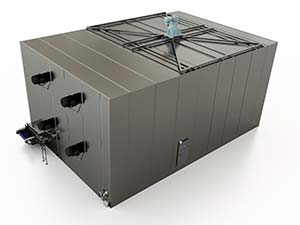

Düsseldorf, Germany-headquartered GEA has announced a pair of additional options that provide more hygiene benefits and less space requirements for its A-Tec spiral freezer customers in the North American market.

Designers have succeeded in positioning the fan and gearbox of the A-Tec outside the freezer – thus removing them from the food area, reducing the number of component surfaces within the unit and significantly improving hygiene. Their external location enables free access to these key components to make cleaning and maintenance much easier, especially as the inside of the freezer is running at -30°C.

Meanwhile, GEA engineers have turned their attention to the overall height of the spiral freezer that is important for users in spaces where headroom is restricted. The standard A-Tec rises to around nine meters overall height, however, now a low profile top drive (LPTD) option has been introduced to reduce that height by around 1.6 meters. This allows it to fit more easily into constrained spaces. The LPTD is situated on the top of the freezer but is driven by a gearbox positioned externally on the side of the freezer. This alternative configuration also allows easy access for cleaning and maintenance.

Meanwhile, GEA engineers have turned their attention to the overall height of the spiral freezer that is important for users in spaces where headroom is restricted. The standard A-Tec rises to around nine meters overall height, however, now a low profile top drive (LPTD) option has been introduced to reduce that height by around 1.6 meters. This allows it to fit more easily into constrained spaces. The LPTD is situated on the top of the freezer but is driven by a gearbox positioned externally on the side of the freezer. This alternative configuration also allows easy access for cleaning and maintenance.

All Features Maintained

Each new development has been achieved without affecting any of the essential features of A-Tec machines, which include: highly effective horizontal airflow that minimizes the temperature rise from the top to the bottom of the spiral, thereby reducing dehydration of the product and improving yield; the unique, sloped, fully welded, fully insulated floor of the A-Tec that removes the need for under-floor heaters, eliminates the risk of accidental floor damage should heaters fail, and provides a very high level of hygiene; and GEA’s sequential coil defrosting system that is simple, effective, easy to clean and allows the freezer to run continuously for up to six days in combination with GEA Static Pressure Control System for ideal air balance control (compared with 8-16 hours for machines without the technology).

Each new development has been achieved without affecting any of the essential features of A-Tec machines, which include: highly effective horizontal airflow that minimizes the temperature rise from the top to the bottom of the spiral, thereby reducing dehydration of the product and improving yield; the unique, sloped, fully welded, fully insulated floor of the A-Tec that removes the need for under-floor heaters, eliminates the risk of accidental floor damage should heaters fail, and provides a very high level of hygiene; and GEA’s sequential coil defrosting system that is simple, effective, easy to clean and allows the freezer to run continuously for up to six days in combination with GEA Static Pressure Control System for ideal air balance control (compared with 8-16 hours for machines without the technology).

“We know how important these features are to our customers, but we also wanted to include the external drive to further enhance hygiene and make maintenance easier, ” said Mathieu Nouhin, the company’s freezing product manager. “With the A-Tec we have achieved a fully open area that’s easy to access, and managed to really improve the product without losing any of the features that have made it so popular with our customers in the past.”

More information is available by visiting GEA’s website: www.gea.com.